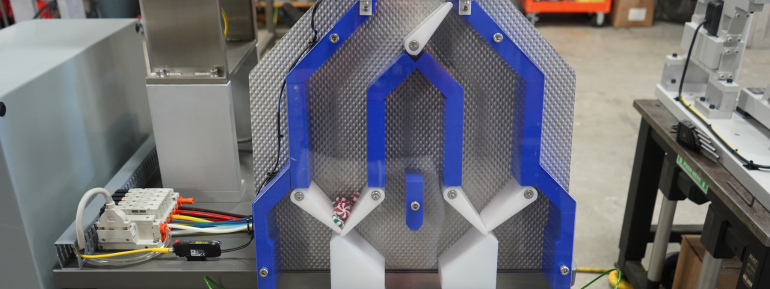

Vibratory Feeder Orients Spray Actuators at 265+ PPM

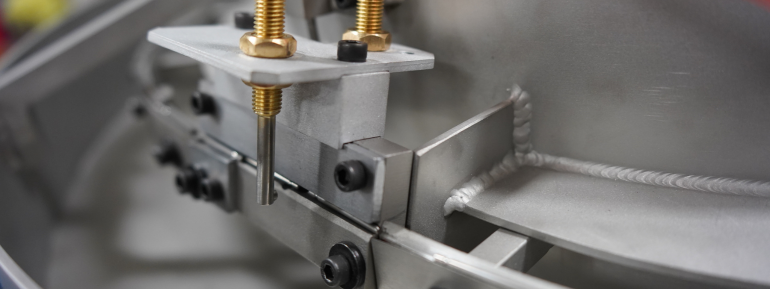

In this application, we designed a 42" vibratory feeder bowl system to efficiently orient spray actuators at a rate exceeding 265 parts per minute. The solution ensures seamless integration with downstream processes and achieves high production rates in a vibratory feeder.

(1).png)