August 21, 2019

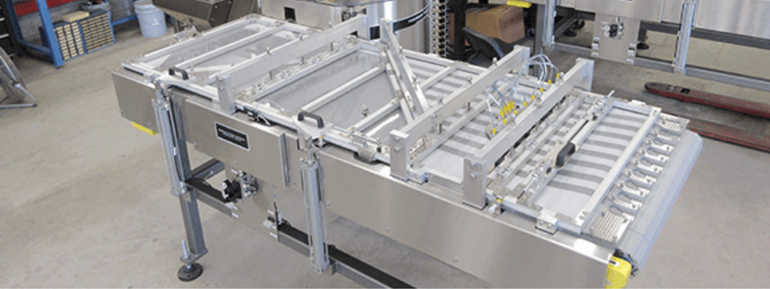

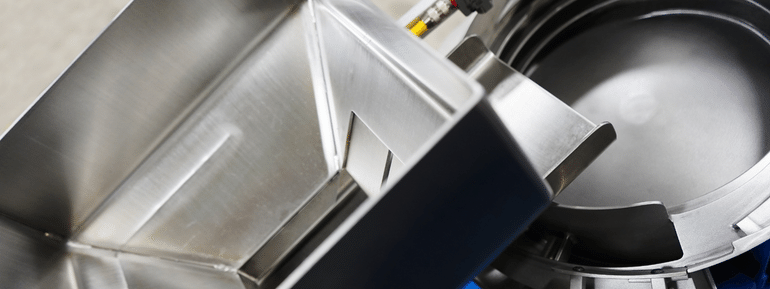

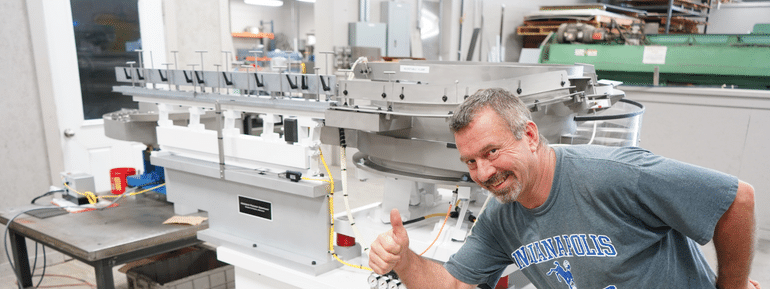

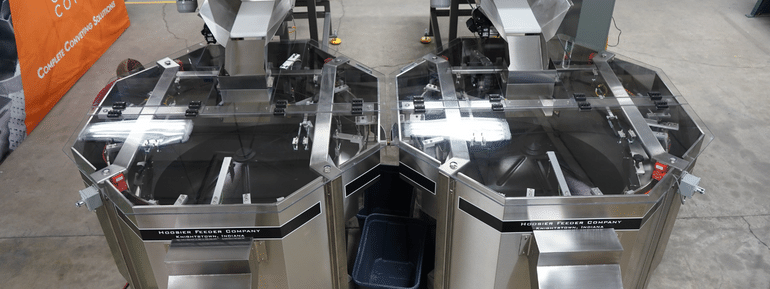

Hoosier Feeder Company / Hoosier Conveyor Company unveils its most versatile centrifugal feeder, the School Lunch Kit Feeder. A robotic industry customer emphasized two implementations that the feeder must hit by the end of its creation. It needed to be a multi-product feeder where it allowed them to feed wrapped spoons, sunflower seeds, packaged chips, cheese sticks, snack bars, crackers, meat sticks, and much more. The other implementation was that the feeder needed to be robotically compatible.