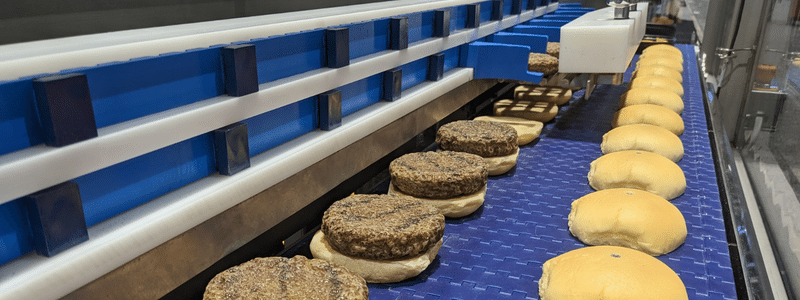

High Speed, Hygienic, Food Product Assembly Solution

Designed to accurately orient and place food products, this new automation solution is ideal for proteins used in ready-to-eat sandwiches, pre-made breakfast sandwiches, frozen meals, and other assembled foods.

How it works

- The patent-pending, protein placement system singulates and orients bulk proteins such as frozen hamburger patties, sausage patties, or egg patties, and drops them into a tray or places them on top of another product such as a bun, biscuit, or muffin.

- The placement system utilizes an Ultimate Orienting Conveyor to singulate and orientate the bulk proteins.

How it helps

- The high-speed automation solution can assemble at rates up to 120 pieces per minute.

- The hygienic design helps reduce human contact and increase production output, all within a compact footprint.

- The system simplifies the pick process for robotic pick-and-place integration by presenting single, oriented product to the robot and allowing for multiple selections at the same time.

- Constructed of 304 stainless-steel, the patent-pending Ultimate Orientating Conveyor is designed for high-pressure wash-down environments and can be easily cleaned without removing tooling.

The product placement system can also be used for non-sanitary applications including secondary packaging assembly and general manufacturing.

Do you have an application?

We are here to discuss your process, and help you choose the right feeding system to optimize your production. Contact us today to discuss your options.

November 28th, 2022

Related Topics: Food and beverage, Product Placement