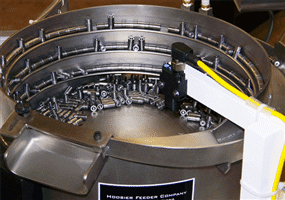

Vibratory feeders are inherently noisy machines. Electromagnetic coils pull and release metal blocks beneath the bowl, usually between 60-120 times per second, to drive part movement causing the parts to vibrate not only against the bowl itself but against adjacent parts. Depending on the material and shape of the parts, the noise level of a feeder system can quickly become damaging to unprotected ears, especially when there is more than one feeder in the area. Fortunately for you, there is an assortment of options to help reduce the overall noise level of your vibratory feeding system.

Vibratory feeders are inherently noisy machines. Electromagnetic coils pull and release metal blocks beneath the bowl, usually between 60-120 times per second, to drive part movement causing the parts to vibrate not only against the bowl itself but against adjacent parts. Depending on the material and shape of the parts, the noise level of a feeder system can quickly become damaging to unprotected ears, especially when there is more than one feeder in the area. Fortunately for you, there is an assortment of options to help reduce the overall noise level of your vibratory feeding system.First of all, there are a variety of coatings that can be applied to vibratory bowl that reduce the noise level as well as reduce wear on parts. Polyurethane is a common and durable coating that works well with plastic parts and will reduce noise cause by parts vibrating against the bowl itself. For heavier, metal parts we may recommend a Line-X coating which provides a durable textured surface with more wear resistance than the typical polyurethane.

If your application will not work well with a bowl coating (i.e. parts with sharp edges, medical applications, etc.), we recommend our aluminum sound enclosures. Our sound enclosures provide an acoustic envelope to the feeding system by surrounding major components with aluminum panels lined with a sound-deadening foam. Enclosures can be customized to allow a hopper to supply the feeder and to make sure operators have all of the access to the machine that they need. For excessively loud applications, combining both a sound enclosure and bowl coatings is also an option.

If your application will not work well with a bowl coating (i.e. parts with sharp edges, medical applications, etc.), we recommend our aluminum sound enclosures. Our sound enclosures provide an acoustic envelope to the feeding system by surrounding major components with aluminum panels lined with a sound-deadening foam. Enclosures can be customized to allow a hopper to supply the feeder and to make sure operators have all of the access to the machine that they need. For excessively loud applications, combining both a sound enclosure and bowl coatings is also an option. Every application is slightly different and may call for more mild or extreme safety measures. Sometimes adding rubber or directional bristle matting to key parts of the system can give you the results you need. Alternatively, building an acoustically isolated room for your feeder system(s) may be more cost and functionally effective, in which case we can give you key considerations for your build.

Contact Us

Whatever your dilemma, Hoosier Feeder Company is prepared to guide you through the process of integrating a noisy feeding system into your production line. We understand employee safety is absolutely crucial, so contact us to learn more about how to control excessive noise caused by vibratory feeders.

January 9, 2018

Related Topics: Vibratory Feeders