One of the most popular features on our Hoosier Feeder Company website is the hopper and elevator capacity calculator. Everyone has heard the old saying that you’re only as strong as your weakest link. The value of determining capacity can’t be discounted.

Here’s why:

Feeder systems are designed and built to improve efficiency. Understanding the product flow through a feed system is paramount to success. When you’re sizing a hopper pre-feeder, you want to create a system that won’t require the operator to have to constantly replenish the supply. At the same time, the system must be engineered to meet operator capacity. The goal is to enable operators to load the feed system and then move on to other parts of the process while remaining ergonomically sound.

Accurately calculating hopper and elevator capacity is critical across all industries but especially necessary for automotive with its heavy metal parts. For example, suppose you need an automotive system that offers 30 minutes of storage and loads a 50-pound box of parts. If the operator is a 100-pound woman, the loading tray needs to be the correct height and length so she isn’t frequently lifting boxes that are beyond her capacity.

Calculating hopper and elevator capacity enables you to balance operator ergonomics with the available environmental footprint and latest technology. When a system is designed within the proper range, operator safety improves and companies are able to focus on optimal capacity.

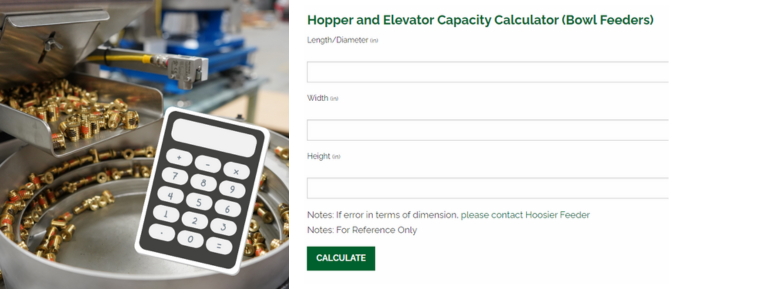

Hopper and Elevator Capacity Calculator

Click here to try the Hoosier Feeder Company hopper and elevator capacity calculator.

To learn more about the resources available from Hoosier Feeder Company, click here. For more information about centrifugal (rotary) feeders and vibratory feeder systems for your business, call us at 1-800-593-7403 or contact us today.

December 4, 2015

Related Topics: Prefeeders