Hoosier Feeder Company has established a sterling reputation for developing high-quality vibratory and centrifugal feeder systems. But we’re also well respected for our dedication to innovation. A key example of our ability to deliver solutions outside established manufacturing needs is our recent work with puck feeder systems.

Puck Feeder Systems for Continuous Motion Assembly

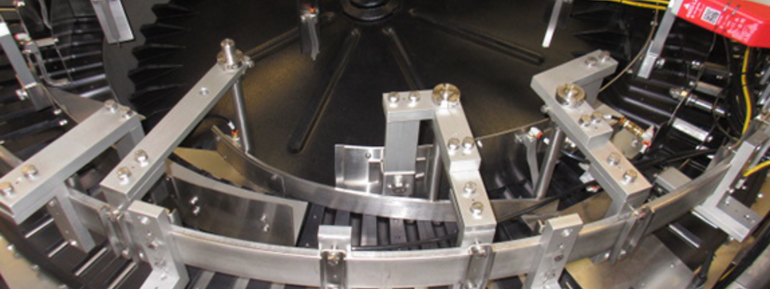

A puck feeder system is a type of centrifugal feeder system that works with continuous motion assembly machines and is designed to transport parts that don’t stand up on their own during the traditional feeding and orienting process. When parts require controlled motion within a feeder system, a puck feeder is an extremely viable option.

Advantages of a Puck Feeder System

Some advantages of a puck feeder system include the following:

- The puck feeder has a round carrier, which stabilizes a part as it goes to various stations in system. If you have a long thin part or an item that won’t stand on its own, a puck feeder can hold it still. For parts with long, thin geometry, where length exceeds width by 5 to 1 (20%), a puck feeder can dramatically improve assembly efficiency.

- Puck feeder systems feature next-level automation, which is ideal for higher speed assembly or complex systems where parts are shifted or assembled during movement. In a puck feeder system, parts don’t leave the puck until they’re fully assembled. Speed is also a factor. A vibratory feeder system typically moves 100-120 parts per minute; a recent puck system created by Hoosier Feeder Company fed 750 parts per minute.

Would your organization benefit from the development of a puck feeder system? Do you need a parts handling system or bowl feeder to handle the complexity of continuous motion machine manufacturing and assembly? If so, contact us today to learn more.

March 8, 2016

Related Topics: Centrifugal Feeders