One of the most common questions we’re asked at Hoosier Feeder Company is how fast a part can be fed in a bowl feeder system. The answer, as you might expect, isn’t as easy as solving a simple math problem. Several factors determine the speed a part can be fed during assembly, including the following:

Part characteristics – What are the dimensions and general make-up of the part?

Part characteristics – What are the dimensions and general make-up of the part?

- Composition of the part materials – What are the parts made of? What are the wear characteristics and coefficient of friction properties?

- Orientation of the part – Which orientation does the part naturally want to travel in a feed system? Is it different from what the project requires?

- Weight of the part – How much does the part weight? What is the part’s center of gravity? How can we use the weight of the part to convert multiple orientations to a common to increase feeder output?

- Current issues – Do you struggle with reliability issues when feeding parts that come from multiple molds or vendors? Is the system simple enough that anyone can fix it when minor issues arise?

- Process limitations – What elements of the process would help to maximize through-put of the feeder system and overall assembly? What is currently the limiting factor in increasing the output of the assembly machine? How can we match the slowest step to the fastest step?

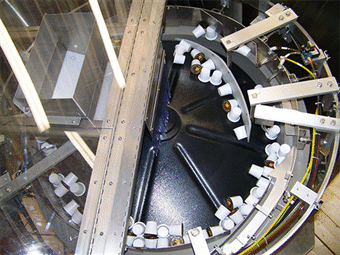

After we’ve considered the factors above and better understand the current process, we can then begin to determine the best concept for a bowl feeder system. A large vibratory bowl feeder can move 45 to 50 feet of parts per minute, or 600 inches per minute. A centrifugal feeder can move as much as 3000 inches per minute.

As you can tell, designing a system to meet your company’s unique requirements requires extensive consideration. In the end, however, a feeder system from Hoosier Feeder Company will be extremely efficient and reliable.

Does your organization need to assess the speed and reliability of its current bowl feeder systems? Contact us today to find out how we can help.

April 22, 2016

Related Topics: Vibratory Feeders, Centrifugal Feeders