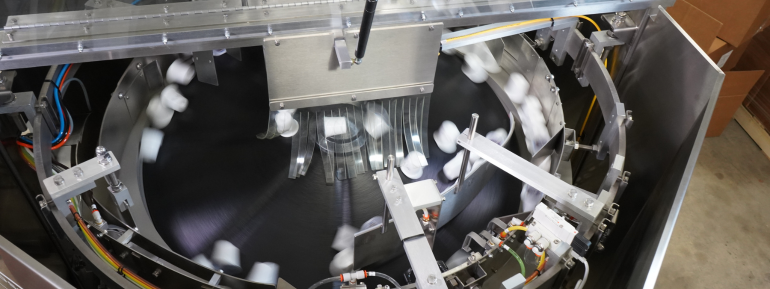

Companies from a variety of industries often make the same mistakes when planning, designing, and installing a centrifugal feeder system. You can avoid these same issues, which will cost significant time and money, by discussing your problem, and potential feeder system solution, before a project begins.

Before the process starts, consider the following:

- Are there new products in the pipeline or future speed requirements under consideration? It is wise to consider the current output of your production line as well as future production requirements to maximize your investment.

- Do you have enough output conveyor length? You need to have enough conveyor and storage to make the system run smoothly without unnecessary starting and stopping the line.

- The size of the hopper must be correct to enable operators to use the system effectively. A hopper, for example, that holds only 7 minutes of parts requires an operator to stand by and frequently empty new parts into the system. A hopper that holds 30 minutes of parts would allow the operator to work on another system concurrently.

- Have all sample part shapes and sizes that the system will need to handle been provided at the start of a project before the design process begins? When the system is built without the full range of product, there is no way to accurately calibrate and ensure dimensional accuracy.

- Do you have actual production parts? If you don’t have them at the time of feeder system construction, your feeder system partner is forced to make educational guesses. By and large, that strategy costs money.

- Has the system been designed to maximize operator access? We always welcome the opportunity to visit your facility to better understand current operation and ensure machine design takes into consideration any existing aisle or obstructions.

What other common mistakes have you seen in the planning, design, and implementation process? To find out more about how Hoosier Feeder Company guards against these issues, click here.

January 5, 2017

Related Topics: Centrifugal Feeders