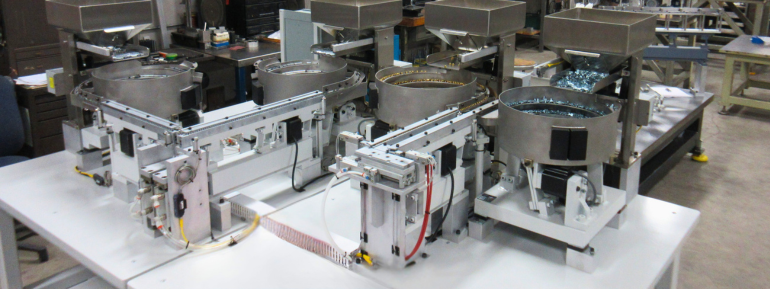

We recently wrapped up a custom vibratory feeder project that highlights the power of thoughtful engineering and system integration. Designed to support robotic arm assembly, this four-system solution is built on a common base frame, maximizing space efficiency while enabling high flexibility in part handling.

A Unified Platform with Built-In Flexibility

What sets this project apart is its shared mechanical infrastructure. All four bowl feeder systems are mounted on a single base, minimizing the system footprint while maintaining accessibility and functionality.

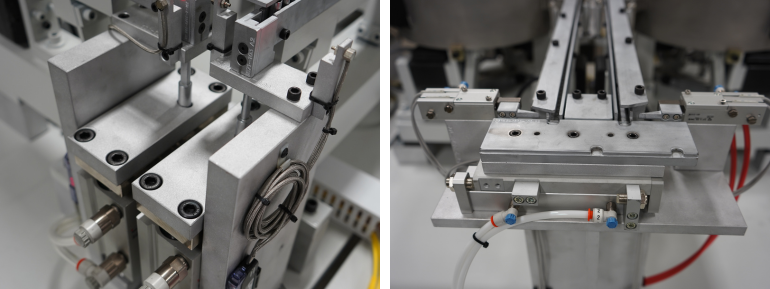

Two of these systems operate through a common dual-pocket shuttle mechanism. Each side of the mechanism’s tooling is designed to accommodate unique part types, allowing for streamlined pick-and-place operations with simple and minimal changeover required between part types.

Additionally, both systems are engineered to present parts in a tightly controlled, robot-friendly orientation, simplifying robot programming and ensuring accurate placement.

By maximizing the robot’s reach and utility, we created a space-saving solution that doesn’t compromise on throughput or precision.

Engineering Efficiency Meets Versatile Automation

This project is a great example of how shared infrastructure and modular tooling can improve efficiency in automated assembly. By combining smart mechanical design with robotic flexibility, we've delivered a solution that's compact, capable, and ready to scale.

Looking to streamline your automation processes?

Our customized vibratory bowl feeder systems are designed for flexibility, efficiency, and robotic integration. If you're exploring ways to optimize your automation footprint without sacrificing performance, we’d love to talk.

Whether you're running multiple part sizes or working within tight space constraints, we can help you engineer a smarter solution. Contact Us to start your next automation project.

May 27, 2025

Related Topics: Vibratory Feeders