Application

In a recent project, a customer needed to singulate and orient plastic bottles in preparation for filling.

- Part: 12 mL plastic bottles

- Rates: Up to 300 parts per minute

The Solution

To optimize their production process, we designed a complete solution including a centrifugal scallop feeder, stainless-steel elevator storage hopper, and integrated conveyor system.

- High-Speed Operation

- Accurate Part Orientation

- Designed for Operator Safely

- Easy to Clean & Maintain

Centrifugal Scallop Feeder & Hopper Elevator

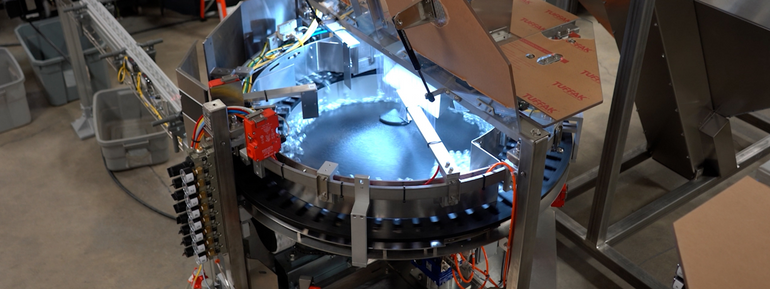

Scallop feeders are ideal for cylindrical parts or parts with a high length-to-diameter ratio. For this application, the centrifugal feeder bowl is designed with Delrin scallop tracks and 304 stainless-steel drop shelves and funnels. It features locking safety switches, Lexan doors for visibility, and LED lighting in the tool area for inspection and maintenance.

The system includes a custom 304 stainless-steel 28 CU FT storage hopper elevator, with a non-contact low-level sensor.

FlexMove Conveyor Integration

The system also includes a flexible chain conveyor with a swerve track and powered transfer. It's designed to seamlessly integrate with the Centrifugal Scallop Feeder, for a complete feeding solution. The 65mm FlexMove flexible chain conveyor by Hoosier Conveyor Company features adjustable tool-less guide rails and aluminum supports.

See it in Action:

Do you have an application?

This type of solution can easily be adapted for a variety of bottle sizes making it ideal for pharmaceutical, medical, cosmetic, and other applications.

We are here to discuss your process, and help you choose the right feeding system to optimize your production. Contact us today to discuss your options.

Related Topics: Centrifugal Feeders, Conveyors