Within a packaging or assembly line, moving product from point A to point B is the name of the game. Whether you are moving the part away from a fixture for picking, accelerating the part into the next process, or transporting it to another area in the facility, linear feeders can provide mobility and flexibility to enhanced production.

Linear Feeder Benefits

Linear Feeders provide many benefits including:

• Maintaining part orientation

• Maximizing throughput with multiple lane feed and output options

• Flexibility in design and layout

• Easy integration with machinery, equipment, and workers

• Adaptability for a multiple parts

• Light part handling and reduced product damage

Types of Linear Feeders

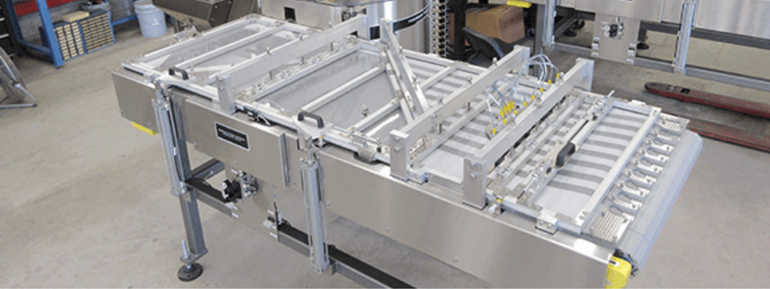

Linear feeders come in a variety of styles. They are designed to move parts from one location to another, sometimes traveling long distances through a facility. Below are 4 types of linear feeders that can easily integrate with bowl feeders and other equipment to optimize productivity.

Conveyors

Available in belt, modular belt, or flexible chain options, conveyors transport parts long distance to connect machinery, equipment, and process flow. Conveyors are typically customized for each application, designed to accommodate long runs, handle any product shape or size, and easily integrate with any type of bowl feeder.

Vibratory Inlines

Using vibration to gently move parts over a distance, inline tracks are often paired with a vibratory feeder to transport parts from the bowl to the pick point while maintaining correct orientation. These feeders are well suited for small parts, typically up to the size of an open hand.

Airveyors

Utilizing high-volume, low-pressure airflow through a series of louvers to quickly transport products, airveyors, also known as air conveyors, are the perfect fit for high-speed conveyance for lightweight parts. Air conveyors are easily integrated with both rotary and vibratory style feeding systems.

Gravity Tracks

A simple linear feeder design, gravity tracks use gravity to stage and stack parts. Typically paired with a vibratory feeder, the gravity track receives parts traveling in the horizontal plane and guides them down an angled track letting gravity do its work to feed the parts into a nest. Gravity tracks work well with systems operating at a low to moderate feed rate and need a part nest to maintain the appropriate part stack-up in the track.

Linear Feeders are available for standard industrial and automation applications, food grade, washdown type applications, and medical grade construction depending on the environment.

Contact Us today to discuss your linear feeder options.

Related Topics: Linear Feeders, Conveyors