Centrifugal feeder systems are designed to ensure manufacturing processes are achieved with a high level of efficiency. Companies in industries such as labelling automation, high-speed packaging, printing, and inspection choose this type of feeder system to handle complex applications that require higher rates of speed. By keeping “hands off” parts, downtime is reduced and productivity is improved.

In a nutshell, centrifugal feeder systems are fast and efficient. But how do they work?

- The process starts with parts being introduced in bulk from a hopper or elevator. If the latter supplies the parts, the flow of the materials is controlled by a photocell. Ensuring the proper level of parts in a centrifugal feeder is paramount. If too many parts are fed at a time, they won’t travel or singulate properly. If too few parts are fed into the system, the unit can’t maximize total output potential. The most complicated part can be oriented and sorted out efficiently by a centrifugal feeder.

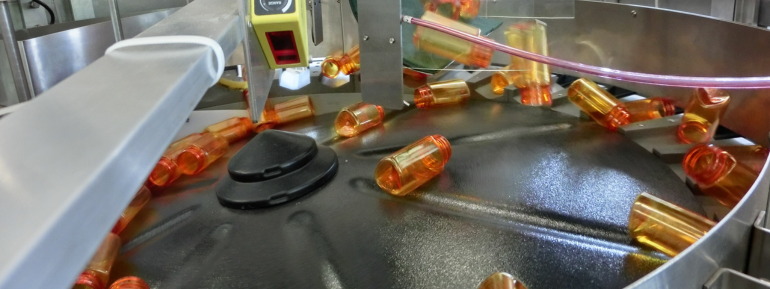

- The parts are then delivered to a rotating center disc in the center of the feeder. The feeder is comprised of a rotating center disc mounted on an angle and a horizontally mounted rotating bowl. The center disc and bowl rotate independently of each other at variable speeds.

- The centrifugal force from the rotation brings the parts to the raised edge of the feeder disc. At its highest point, the edge of the disc is slightly higher than the running surface of the bowl, which enables the parts to load.

- The centrifugal force of the system then propels the parts past the mechanical and pneumatic tooling, which converts as many parts as possible to a common orientation. Other tooling features in the system will reject anything not properly oriented.

- The parts flow through the system until they reach their final assembly or packaging destination.

Businesses often choose centrifugal feeder systems because they are gentle on parts due to low circulation. The less the circulation, the fewer scuffs or surface imperfections result from part to part contact. Centrifugal systems also have higher feed rates, are quieter than vibratory feeder systems, and require little maintenance and upkeep.

Would your organization benefit from the installation of a centrifugal feeder system? Contact us today to learn more.

Related Topics: Centrifugal Feeders