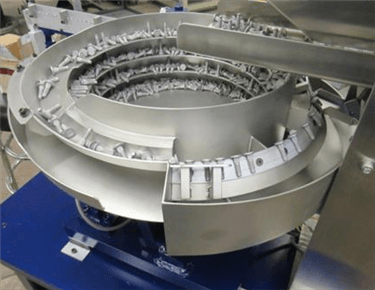

A quick glance at all the large pieces of metal that constitute an automobile, you’d be forgiven for not thinking about all the little items that often connect them together. Feeder systems ensure all the parts of your car correctly get where they need to be to ensure assembly proceeds smoothly. Head rests, speedometer needles, clips in your seatbelt – Hoosier Feeder Company creates the equipment and processes that pull it all together. Although Hoosier Feeder has expertise creating centrifugal and vibratory feeder systems, about 90% of the systems used in auto manufacturing and assembly are of the vibratory variety.

The Perfect Automotive Vibratory Feeder System

Here’s how we create the perfect vibratory feeder system for the automotive industry:

Here’s how we create the perfect vibratory feeder system for the automotive industry:

- Simplicity – Automotive parts feeder systems should be easy to operate. Should any issues arise, it is best that even the non-skilled labor can easily fix it.

- Robust – The feeder system must be made with solid construction and feature hardened machine details to handle the extreme environment of auto manufacturing and assembly.

- Lasting – A vibratory feeder system should last a long time to ensure a return on investment. At Hoosier Feeder Company, we make sure all systems have good wear characteristics so they don’t wear out prematurely.

- Safety – Our feeder systems are designed to maximize safety while still allowing for access from various points to ensure assembly efficiency.

- Optimized Feeding & Noise Reduction – Metal parts make noise, but that doesn’t mean sound can’t be limited. Our systems are designed to be ergonomically sound and to reduce noise, ensuring decibel levels fall under OAHA levels (below 85 dba). Aluminum sound enclosures, for example, can be lined with 1 inch acoustical foam to reduce decibel levels.

- Precision – We grind both sides of machine-base plates, which provides a flat and true service to build your feeder system foundation upon.

Are your automotive vibratory feeder systems working at optimal efficiency and returning the highest ROI possible? If not, let us make your life easier.

If you are interested in learning more about Hoosier Feeders automotive industry expertise, visit our Automotive Feeder Systems page or read about how we helped Ford Motors with their F-150 Truck assembly. Or contact us directly to learn how we can develop the perfect vibratory feeder system for your organization's specific objectives.

Related Topics: Automotive, Vibratory Feeders